Team work

S.O.N.I.A. prides itself of its hard work and teamwork; we believe that knowledge is best obtained through hands-on experience and collaboration. That is why we always strive for an educational environment open for all who desire to learn.

Sharing

Knowledge shouldn’t have limits. That is why S.O.N.I.A. makes all projects open source for all teams to use. The club currently shares all GitHub repositories for other participating teams and enthusiasts alike to aid in the conception of their own autonomous submarine.

Constant innovation

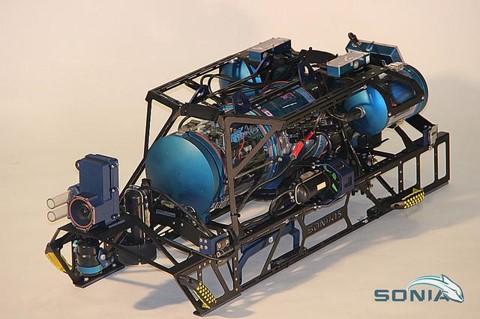

Improvement and innovation on preexisting prototypes is what makes each generation of autonomous submarines better!

Facts about us…

Since 1999

S.O.N.I.A. celebrated its 25 years.

25 Robosub event

Our main goal is to participate in the annual Robosub event.

149

Repositories on GitHub.

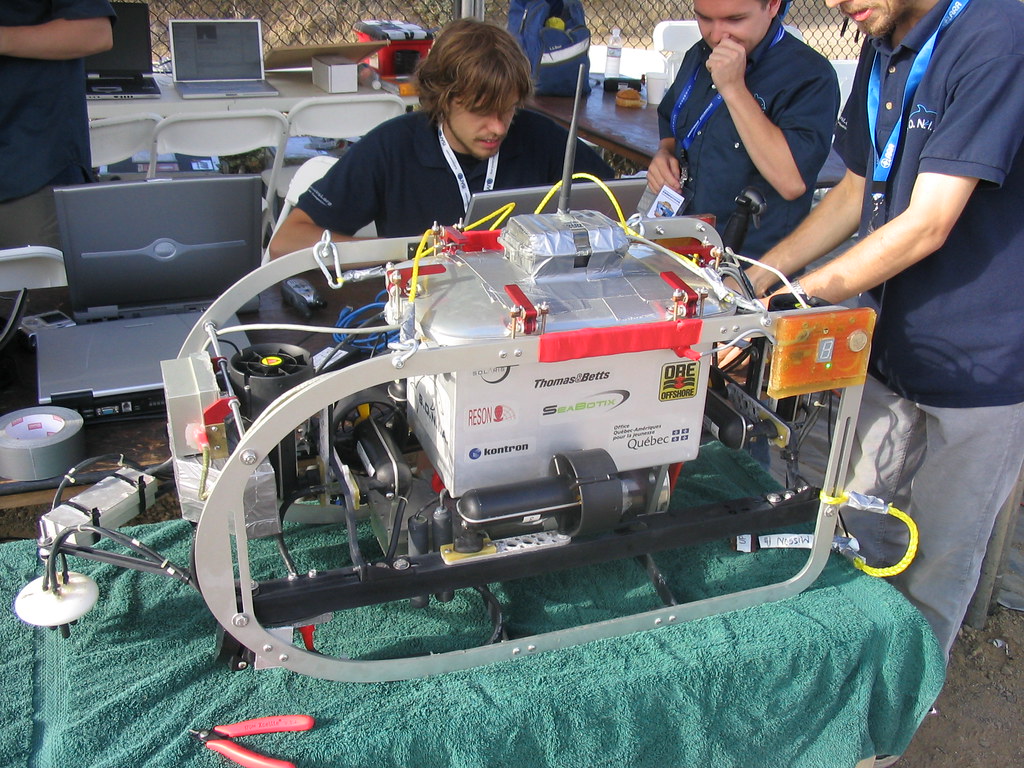

Multidisciplinary

Our club is made up of students from programs in mechanics, electrical, automated production and software engineering.

10 prototypes

Since the creation of S.O.N.I.A. there have been 10 generations of autonomous submarines.

Complex tasks

S.O.N.I.A. has to perform several complex tasks such as identifying obstacles, picking up and dropping objects, following acoustic signals… All without human intervention!

200+

Contributors over the years.

Engineering University

S.O.N.I.A. is a scientific club from École de Technologie Supérieure in Montreal,QC.

History

SONIA I (1999-2000)

SONIA II (2001)

SONIA III (2002-2003)

SONIA IV (2004-2005)

SONIA V (2006-2008)

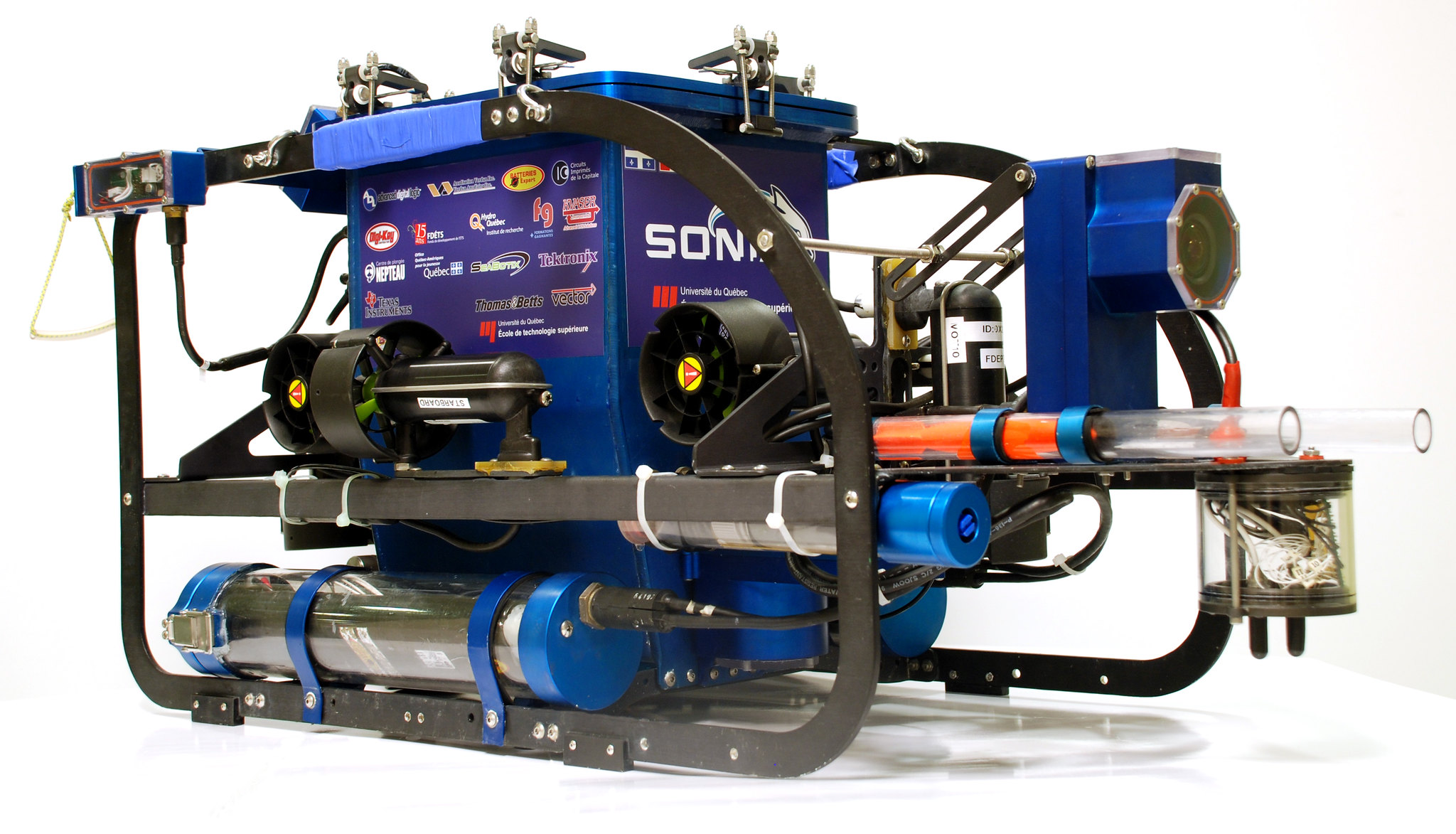

SONIA VI (2009-2010)

SONIA VII (2011-2013)