Meet the mechanical team, responsible for designing, building, and maintain the various parts of the submarine. These parts include:

- The enclosure;

- The main hub

- The mounts and rack systems;

- Actuators.

The hull of AUV8 is our most recent submarine. It was designed using SolidWorks and machined in a CNCs. In total, more than 250 hours were spent machining AUV8’s hull.

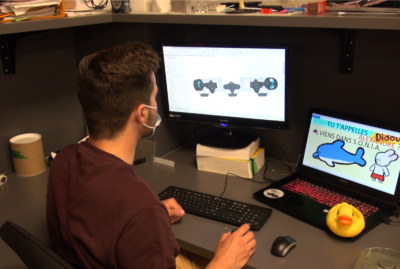

S.O.N.I.A. utilizes SolidWorks, provided by one of its longstanding sponsors, for 3D design. CNC and additive manufacturing are then employed to fabricate the parts.

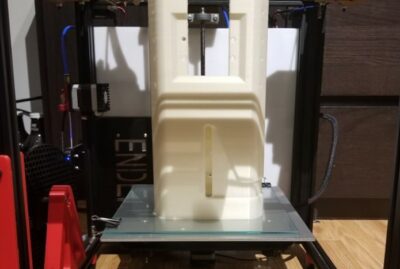

Additionally, the team is continually generating new ideas and supporting other departments to enhance the AUV’s efficiency. Moreover, the mechanical team collaborates closely with the electrical team to integrate various electrical systems into the submarine. Such as, a clip-based, toolless rack system for AUV8, developed by the mechanical team that has allowed the electrical team to remove components without using tools. This custom system was entirely created using additive manufacturing.

Lastly, the team is responsible for conducting regular maintenance to uphold the submarine’s integrity.

Mechanical projects

3D Printing

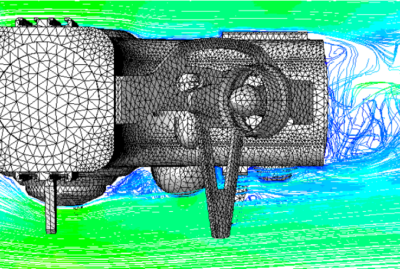

CFD Simulation

Machining